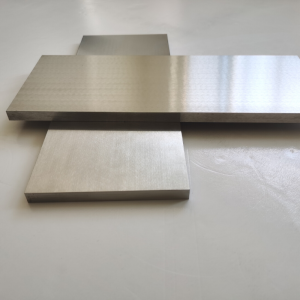

MoAl35wt% Molybdenum Aluminum Alloy Ingot Step Alloy for PVD Coating

Chrome Silicon

MoAl35wt% Molybdenum Aluminum Alloy Ingot Step Alloy for PVD Coating,

,

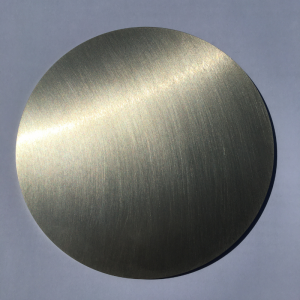

The fabrication of Chronium Silicon Sputtering Targets comprises the following steps:

1.Vacuum melting of Silicon and Chronium to obtain step alloys.

2.Powder grinding, packed and evacuation.

3.Hot isostatic pressing treatment to get semi-finished products.

4.Machining the rough chromium-silicon alloy sputtering target material to obtain the chromium-silicon alloy sputtering target material.

CrSi is often used as the high resistance film material, it features the high resistance, stability and low temperature coefficient of resistance. Chronium and Silicon could produce many silicide phases like Cr3Si , Cr5Si3, , CrSi , CrSi2. The production process, composition and Heat treatment process of the CrSi film greatly affects its performance.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Silicon Sputtering Materials according to Customers’ specifications. For more information, please contact us.Quick Details

Place of Origin:

Beijing, China

Brand Name:

Richmat

Model Number:

GH00060

Application:

Vacuum Coating

Shape:

Lumps Pellets Granules

Material:

Molybdenum Aluminum

Chemical Composition:

MoAl35wt%

Packing:

Iron drum

Product Name

MoAl35wt% Lumps

Shape

Lumps, Pieces

Purity

99.99%

MOQ

1 piece