Manufacturer for Evaporative Crucible Material - V Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Manufacturer for Evaporative Crucible Material - V Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Vanadium Sputtering Target Description

Vanadium is a hard, ductile metal with a silvery-gray appearance. It is harder than most metals and exhibits good corrosion resistance against alkalis and acids. Its melting point is 1890℃, and boiling point is 3380℃. Its atomic number is 23, and atomic weight is 50.9414. It has a face-centered cubic structure and oxidation states in its compounds of +5, +4, +3 and +2. It has high melting point, ductility, hardness, and corrosion resistance.

Vanadium is extensively used in a number of industries and applications, such as jet engines, high speed air frames, nuclear reactors and alloying of steel.

High purity Vanadium sputtering target is a critical material for solar cells and optical lens coatings.

Chemical Analysis

|

Purity |

99.7 |

99.9 |

99.95 |

99.99 |

|

Fe |

≤0.1 |

≤0.05 |

≤0.02 |

≤0.01 |

|

Al |

≤0.2 |

≤0.05 |

≤0.03 |

≤0.01 |

|

Si |

≤0.15 |

≤0.1 |

≤0.05 |

≤0.01 |

|

C |

≤0.03 |

≤0.02 |

≤0.01 |

≤0.01 |

|

N |

≤0.01 |

≤0.01 |

≤0.01 |

≤0.01 |

|

O |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.03 |

|

Impurity in total |

≤0.3 |

≤0.1 |

≤0.05 |

≤0.01 |

Vanadium Sputtering Target Packaging

Our Vanadium sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s vanadium sputtering targets offer superb purity and consistency. They are available in a variety of forms, purity, sizes and prices. We specialise in high purity thin film coating materials with excellent properties, as well as the highest possible density and smallest possible average grain size, for die coating, decoration, automotive parts, low E glass, semiconductor integrated circuits, thin film resistors, graphic displays, aerospace, magnetic recording, touch screens, thin film solar cells and other physical vapour deposition (PVD) applications. Please send us an enquiry for current pricing on sputtering targets and other deposition materials not listed.

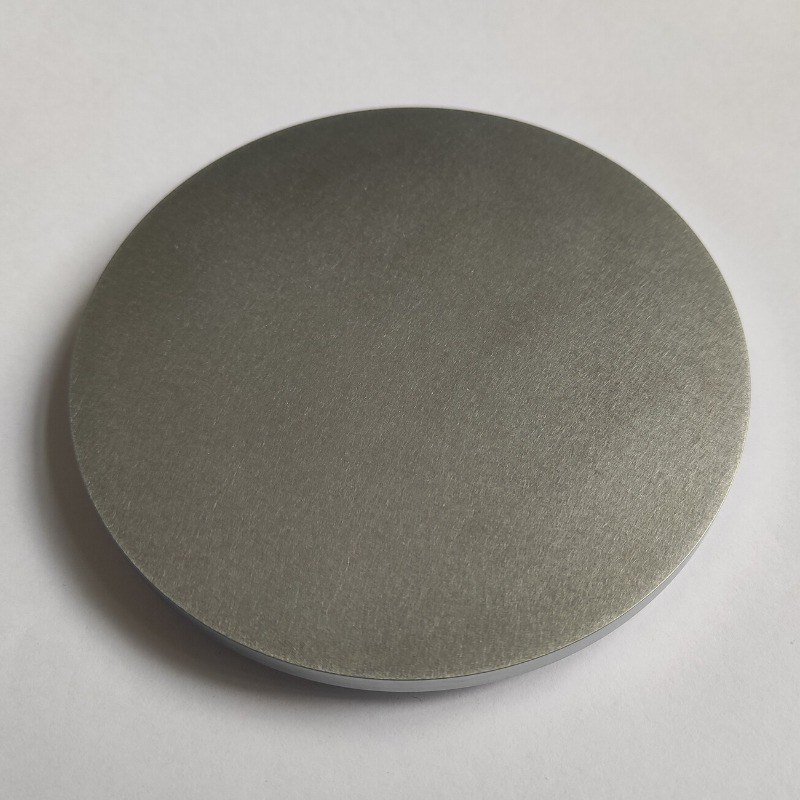

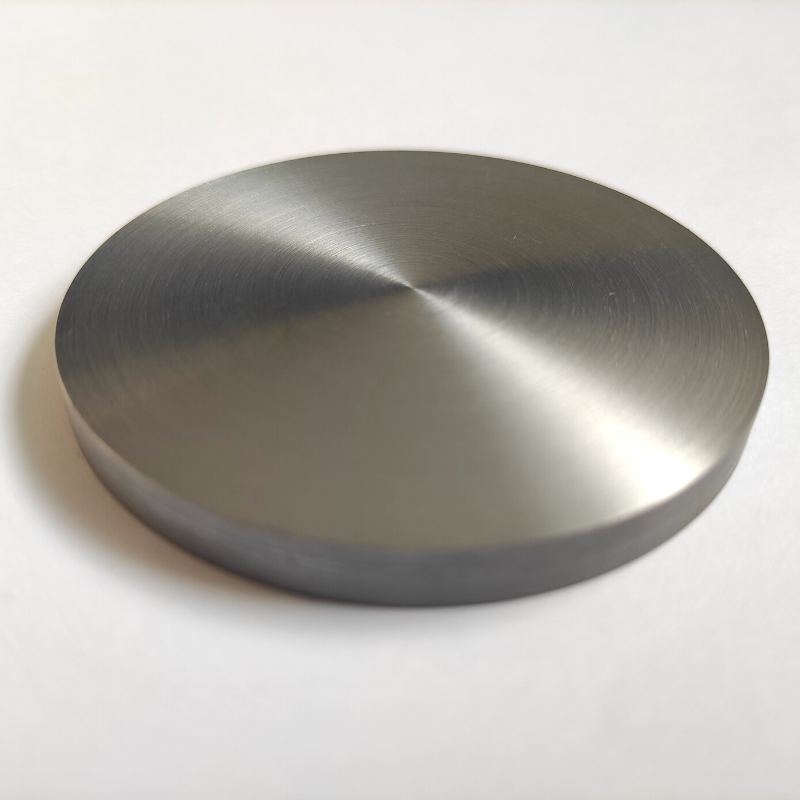

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Manufacturer for Evaporative Crucible Material - V Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Germany, Egypt, Peru, You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.