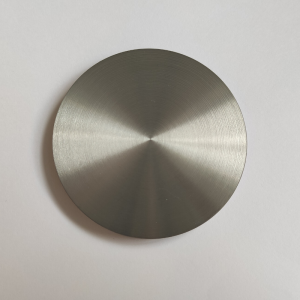

TiAl Sputtering Target High Purity Thin Film Pvd Coating Custom Mere

Titanium aluminum

Vidiyo

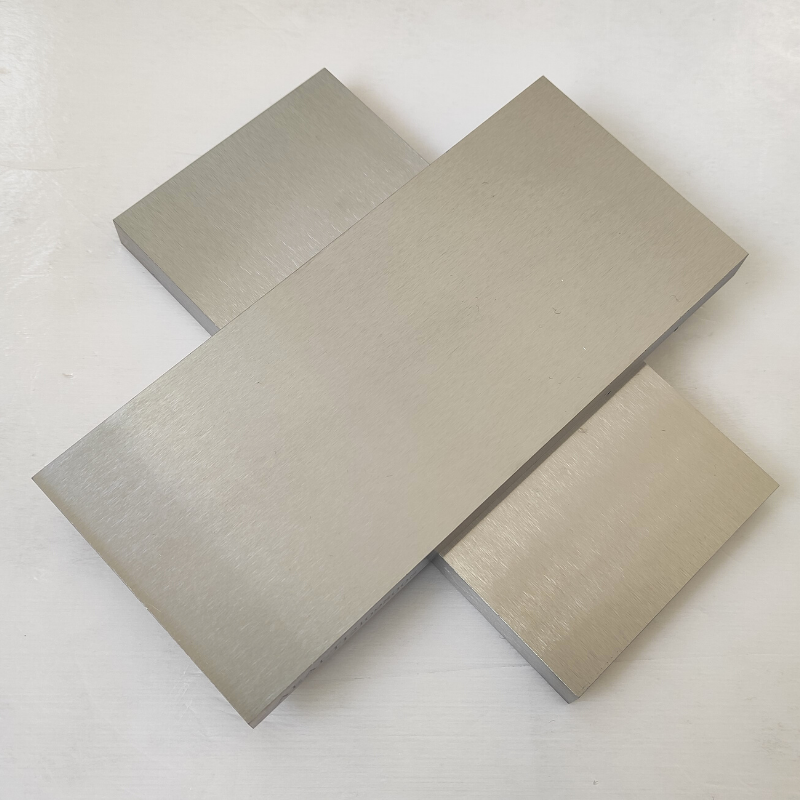

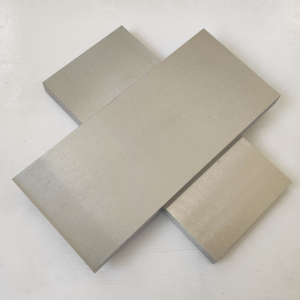

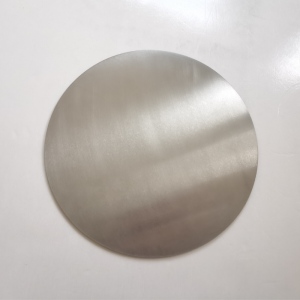

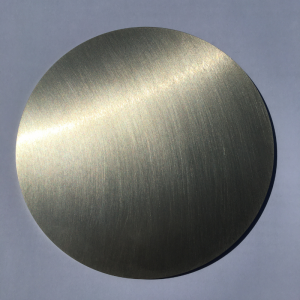

Titanium Aluminom sputtering Target nkọwa

Ihe achọrọ nke ebumnuche ebumnuche maka mkpuchi sputter dị elu karịa nke ụlọ ọrụ ihe ọdịnala. Microstructure otu nke ebumnuche na-emetụta arụmọrụ sputtering ozugbo. Anyị nwere usoro njikwa mma zuru oke ma anyị na-ahọrọ akụrụngwa dị ọcha ma gwakọta ha nke ọma iji hụ na ịdị n'otu. Titanium Aluminom alloy sputtering target bụ nke a na-emepụta site na usoro ịpị ọkụ ọkụ.

Ebumnuche Titanium Aluminom sputtering anyị nwere ike inye mkpuchi nitride na-eguzogide oxidation pụtara ìhè, Titanium aluminum nitride (TiAlN). TiAlN bụ isi ihe dị ugbu a dị ka ihe nkiri maka ịkpụ ngwaọrụ, akụkụ slide na mkpuchi tribo. Ọ nwere nnukwu isi ike, ike siri ike, ịrụ ọrụ na-eguzogide ọgwụ na okpomọkụ oxidation.

Ebumnuche TiAl anyị na-ahụkarị na akụrụngwa ha

| Ti-75Al na% | Ti-70Al na% | Ti-67Al na% | Ti-60Al na% | Ti-50Al na% | Ti-30Al na% | Ti-20Al na% | Ti-14Al na% | |

| Ịdị ọcha (%) | 99.7 | 99.7 | 99.7 | 99.7 | 99.8/99.9 | 99.9 | 99.9 | 99.9 |

| Njupụta(g/cm3) | 3.1 | 3.2 | 3.3 | 3.4 | 3.63/3.85 | 3.97 | 4.25 | 4.3 |

| Gmmiri ozuzo Nha(µm) | 100 | 100 | 100 | 100 | 100/- | - | - | - |

| Usoro | HIP | HIP | HIP | HIP | HIP/VAR | VAR | VAR | VAR |

Titanium Aluminom Sputtering Target Nkwakọ ngwaahịa

Ebumnuche Titanium Aluminom sputter anyị bụ akara nke ọma ma kpọọ ya n'èzí iji hụ na njirimara na njikwa mma dị mma. A na-akpachapụ anya nke ukwuu iji zere mmebi ọ bụla nwere ike ịkpata n'oge nchekwa ma ọ bụ njem.

Nweta kọntaktị

Ebumnuche RSM's Titanium Aluminom sputtering bụ nke ịdị ọcha dị oke elu yana otu. Ha dị n'ụdị dị iche iche, ịdị ọcha, nha, na ọnụ ahịa.

Anyị nwere ike ịnye ụdị ụdị geometric dị iche iche: tubes, arc cathodes, planar ma ọ bụ nke a na-eme omenala, yana oke nke Aluminom. Ngwaahịa anyị nwere ezigbo ihe eji arụ ọrụ, microstructure na-arụkọ ọrụ ọnụ, elu a na-egbu maramara na-enweghị nkewa, pores, ma ọ bụ mgbawa.

Anyị ipuiche na-amị elu-ọcha mkpa film mkpuchi ihe na magburu onwe arụmọrụ yana ndị kasị elu kwere omume njupụta na kacha nta kwere omume nkezi ọka nha maka ojiji na ebu mkpuchi, ịchọ mma, ụgbọala akụkụ, ala-E iko, ọkara-eduzi Integrated circuit, obere ihe nkiri. eguzogide, graphic ngosi, aerospace, magnetik ndekọ, ihuenyo mmetụ, mkpa film anyanwụ batrị na ndị ọzọ anụ ahụ vepo ngwa nkwụnye ego (PVD). Biko zitere anyị ajụjụ maka ọnụahịa ugbu a maka ebumnuche ịgbasa na ihe nkwụnye ego ndị ọzọ edepụtaghị.