Tupu mgbe ahụ, ọtụtụ ndị ahịa jụrụ ndị ọrụ ibe si RSM Technology Department banyere titanium alloy. Ugbu a, m ga-achọ ichikota isi ihe ndị a maka gị gbasara ihe metal titanium alloy ji mee. Enwere m olileanya na ha nwere ike inyere gị aka.

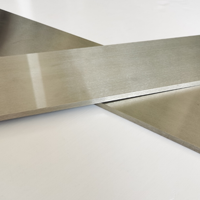

Titanium alloy bụ alloy mere nke titanium na ihe ndị ọzọ.

Titanium bụ kristal dị iche iche, nke nwere ebe agbaze nke 1720 ℃. Mgbe okpomọkụ dị ala karịa 882 ℃, ọ nwere ihe owuwu lattice hexagonal juru eju, nke a na-akpọ α Titanium; O nwere ihe owuwu cubic gbadoro ụkwụ na ya karịa 882 ℃, nke a na-akpọ β Titanium. N'iji njirimara dị iche iche nke ihe owuwu abụọ dị n'elu nke titanium, a na-agbakwunye ihe ndị na-edozi ahụ kwesịrị ekwesị iji jiri nwayọọ nwayọọ gbanwee mgbanwe mgbanwe okpomọkụ ya na ọdịnaya nke oge iji nweta titanium alloys dị iche iche. N'ime ụlọ okpomọkụ, titanium alloys nwere ụdị matrix atọ dị iche iche, na titanium alloys na-ekewa n'ime atọ ndị a: α Alloy (α + β) Alloy na β Alloy. Na China, TA, TC na TB gosipụtara ya n'otu n'otu.

α titanium alloy

Ọ bụ α Single frasi alloy esịnede frasi siri ike ngwọta bụ α Oge, kwụsiri ike Ọdịdị, elu eyi eguzogide karịa titanium dị ọcha, ike ọxịdashọn na-eguzogide. N'okpuru okpomọkụ nke 500 ℃ ~ 600 ℃, ọ ka na-edobe ike ya na creep eguzogide, ma enweghị ike ike site okpomọkụ ọgwụgwọ, na ụlọ okpomọkụ ike adịghị elu.

β titanium alloy

Ọ bụ β Alloy otu-phase mejupụtara nke usoro siri ike ngwọta nwere ike dị elu na-enweghị ọgwụgwọ okpomọkụ. Mgbe emenyụchara na ịka nká, a na-eme ka alloy dịkwuo ike, na ike okpomọkụ nke ime ụlọ nwere ike iru 1372 ~ 1666 MPa; Otú ọ dị, nkwụsi ike nke okpomọkụ adịghị mma ma ọ dịghị mma maka iji ya mee ihe na okpomọkụ dị elu.

α + β titanium alloy

Ọ bụ alloy nke abụọ nwere ezigbo ihe zuru oke, nkwụsi ike nhazi dị mma, ịdị mma siri ike, plasticity na njirimara nrụrụ okpomọkụ. Enwere ike iji ya mee ihe maka nhazi nrụgide na-ekpo ọkụ, nkwụsị na ịka nká iji mee ka alloy sie ike. The ike mgbe okpomọkụ ọgwụgwọ bụ banyere 50% ~ 100% elu karịa na mgbe annealing; Ike okpomọkụ dị elu, nwere ike ịrụ ọrụ na 400 ℃ ~ 500 ℃ ruo ogologo oge, na nkwụsi ike ya na-erughị α Titanium alloy.

N'etiti atọ titanium alloys α Titanium alloys na α + β Titanium alloy; α Titanium alloy nwere igwe kachasị mma, α+ P Titanium alloy na-ewere ọnọdụ nke abụọ, β Titanium alloy adịghị mma. α Koodu nke titanium alloy bụ TA, β Koodu nke titanium alloy bụ TB, α + β koodu nke alloy titanium bụ TC.

Enwere ike kewaa alloys Titanium n'ime alloys na-eguzogide okpomọkụ, alloys siri ike dị elu, alloys na-eguzogide corrosion (titanium molybdenum, titanium palladium alloys, wdg), alloys dị ala okpomọkụ na alloys ọrụ pụrụ iche (ihe nchekwa ígwè titanium ígwè hydrogen na titanium nickel memory alloys). ) dị ka ngwa ha si dị.

Ngwọta okpomọkụ: titanium alloy nwere ike nweta nhazi usoro dị iche iche na nhazi site na ịhazi usoro ọgwụgwọ okpomọkụ. A na-ekwenyekarị na mma equiaxed microstructure nwere ezigbo plasticity, nkwụsi ike okpomọkụ na ike ike ọgwụgwụ; Ọdịdị acicular nwere ike mgbawa dị elu, ike na-akpụ akpụ na ike mgbaji; Ngwakọta agwakọta na anụ ahụ acicular nwere ọrụ zuru oke karịa

Oge nzipu: Ọktoba 26-2022