Hot sale Al Pellets - NiAl Niobium Aluminum high purity sputtering target PVD coating – Rich

Hot sale Al Pellets - NiAl Niobium Aluminum high purity sputtering target PVD coating – Rich Detail:

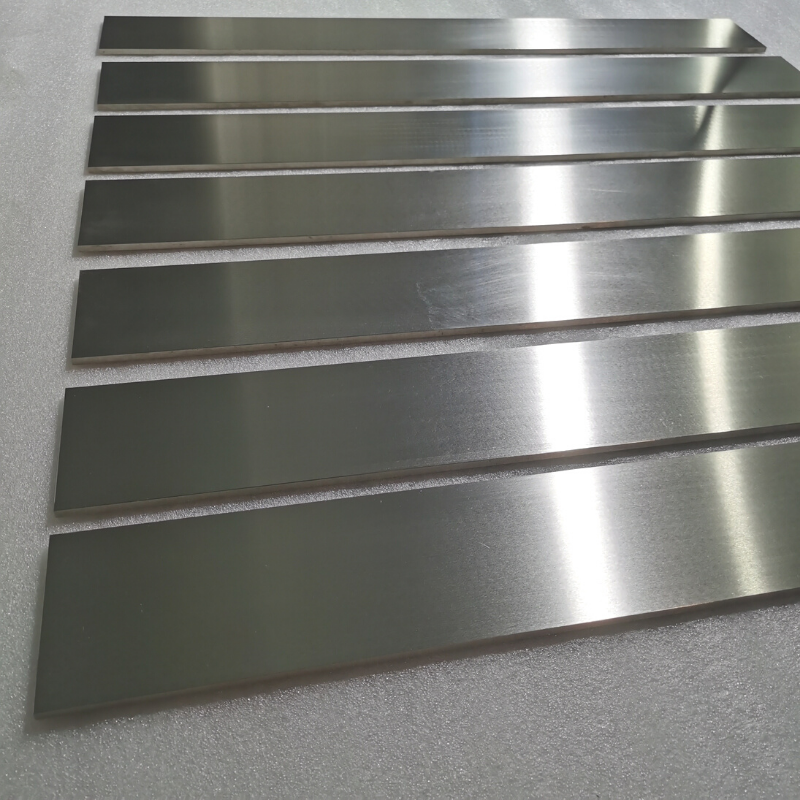

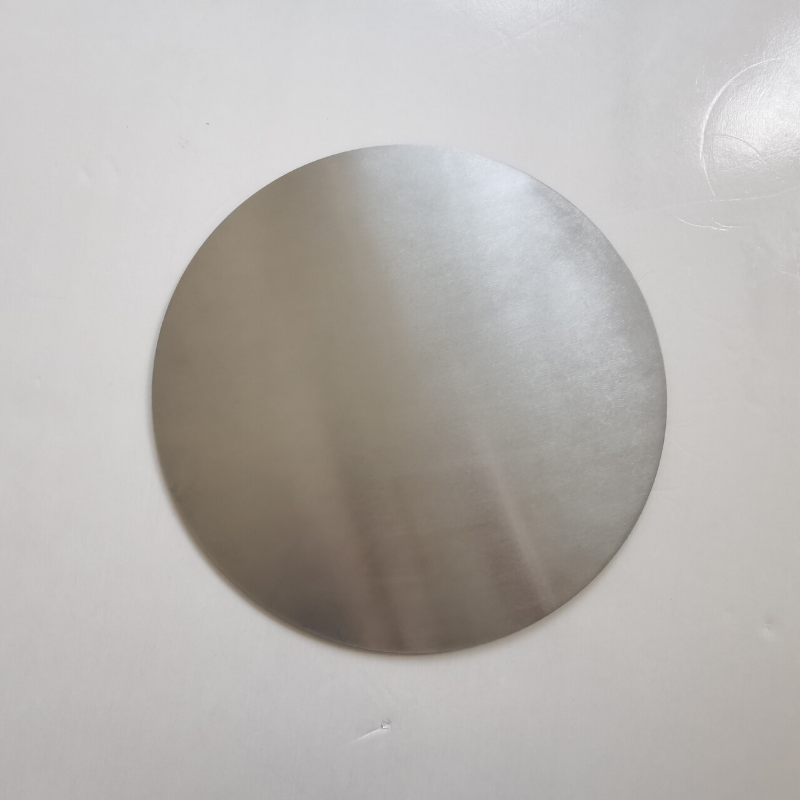

NiAl Niobium Aluminum high purity sputtering target PVD coating,

high purity factory price primary source,

Nickel Aluminum alloy sputtering target is produced by means of vacuum melting and power metallurgy. Mixing Aluminum and Nickel in an amount necessary to provide NiAl casting ingot. The casting ingot is then cut to form the desired target shape. It has high consistency, refined grain size and homogeneous microstructure, without gas puff or pores.

Owing to its excellent combination of the coating and substrate material, the NiAl coating has good performance under 700℃. Now the NiAl sputtering target is extensively used in wear resistant coatings, including cutting tools, molds, automotive and construction industries.

Rich Special Materials is a Manufacturer of Sputtering Target and could produce Nickel Aluminum Sputtering Materials according to Customers’ specifications. For more information, please contact us.The targets are prepared by blending Aluminum and Niobium powders followed by compaction to full density. The thus compacted materials are optionally sintered and are then formed into the desired target shape. It has high purity, homogeneous microstructure, simple process method and competitive cost, and is used in a number of applications and industries. Aluminum-niobium alloys present considerable strength and hardness, excellent chemical stability, and are perfect for environments with an elevated temperature level. Besides,Nb-Al alloy could be used as superconductivity materials. It features high melting point and low density, and is extensively used in aerospace, marine, industrial gas turbine, aircraft, nuclear reactor fuel, petrochemical equipment industries. Aluminum-niobium alloys are also the important addition to produce high performance Titanium alloy.

SEND EMAIL TO US

Product detail pictures:

Related Product Guide:

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Hot sale Al Pellets - NiAl Niobium Aluminum high purity sputtering target PVD coating – Rich , The product will supply to all over the world, such as: Greenland, Oslo, Sri Lanka, With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!