Nrog rau kev txhim kho ntawm tib neeg cov qauv kev ua neej thiab kev txhim kho txuas ntxiv ntawm kev tshawb fawb thiab thev naus laus zis, cov neeg muaj kev xav tau ntau dua thiab siab dua rau kev ua haujlwm ntawm kev hnav-resistant, corrosion-resistant thiab high-temperature resistant decorating txheej khoom. Tau kawg, lub txheej kuj tuaj yeem ua kom zoo nkauj xim ntawm cov khoom no. Tom qab ntawd, qhov txawv ntawm kev kho cov phiaj electroplating thiab sputtering lub hom phiaj yog dab tsi? Cia cov kws tshaj lij los ntawm Technology Department of RSM piav qhia rau koj.

Electroplating phiaj

Lub hauv paus ntsiab lus ntawm electroplating yog raws li cov electrolytic refining tooj liab. Thaum electroplating, cov electrolyte uas muaj cov hlau ions ntawm txheej plating feem ntau yog siv los npaj cov tshuaj plating; Immersing cov khoom hlau yuav tsum tau plated rau hauv cov tshuaj plating thiab txuas nrog qhov tsis zoo electrode ntawm DC fais fab mov raws li cathode; Cov hlau coated yog siv los ua cov anode thiab txuas nrog qhov zoo electrode ntawm DC fais fab mov. Thaum siv cov hluav taws xob qis DC tam sim no, cov hlau anode yaj hauv cov tshuaj thiab dhau los ua cation thiab txav mus rau cathode. Cov ions no tau txais electrons ntawm lub cathode thiab raug txo rau cov hlau, uas yog them rau cov khoom hlau yuav tsum tau plated.

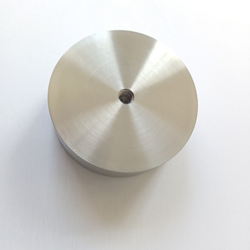

Sputtering Target

Lub hauv paus ntsiab lus yog tsuas yog siv lub teeb tawm mus rau kev sib tsoo argon ions ntawm lub hom phiaj nto, thiab cov atoms ntawm lub hom phiaj yog ejected thiab tso rau ntawm lub substrate nto los ua ib tug nyias zaj duab xis. Cov khoom thiab qhov sib xws ntawm sputtered films yog zoo dua li cov vapor deposited films, tab sis lub deposition ceev yog qeeb npaum li cas ntawm vapor deposited films. Cov khoom siv tshiab sputtering yuav luag siv cov hlau nplaum muaj zog rau kauv electrons kom ceev cov ionization ntawm argon nyob ib ncig ntawm lub hom phiaj, uas ua rau kom muaj kev sib tsoo ntawm lub hom phiaj thiab argon ions thiab txhim kho tus nqi sputtering. Feem ntau ntawm cov hlau plating zaj duab xis yog DC sputtering, thaum cov ntaub ntawv tsis-conductive ceramic magnetic yog RF AC sputtering. Lub hauv paus ntsiab lus tseem ceeb yog siv glow tawm hauv lub tshuab nqus tsev kom tawg rau saum npoo ntawm lub hom phiaj nrog argon ions. Cov cations hauv plasma yuav nrawm nrawm mus rau qhov tsis zoo electrode nto raws li cov khoom siv sputtered. Qhov kev foob pob no yuav ua rau lub hom phiaj cov khoom ya tawm thiab tso rau ntawm lub substrate los ua ib zaj duab xis nyias.

Kev xaiv cov hom phiaj ntawm cov khoom siv

(1) Lub hom phiaj yuav tsum muaj lub zog zoo txhua yam thiab tshuaj lom neeg ruaj khov tom qab tsim cov yeeb yaj kiab;

(2) Cov ntaub ntawv zaj duab xis rau cov reactive sputtering zaj duab xis yuav tsum yooj yim los tsim ib tug compound zaj duab xis nrog cov tshuaj tiv thaiv roj;

(3) Lub hom phiaj thiab lub substrate yuav tsum tau sib sau ua ke ruaj khov, txwv tsis pub, cov khoom siv zaj duab xis nrog lub zog zoo nrog lub substrate yuav tsum tau saws, thiab cov yeeb yaj kiab hauv qab yuav tsum tau sputtered ua ntej, thiab tom qab ntawd cov txheej txheem zaj duab xis yuav tsum tau npaj;

(4) Ntawm qhov chaw ua tau raws li qhov yuav tsum tau ua ntawm cov yeeb yaj kiab, qhov sib txawv me me ntawm thermal expansion coefficient ntawm lub hom phiaj thiab lub substrate, qhov zoo dua, thiaj li txo qhov cuam tshuam ntawm thermal stress ntawm sputtered zaj duab xis;

(5) Raws li daim ntawv thov thiab kev ua tau zoo ntawm cov yeeb yaj kiab, lub hom phiaj siv yuav tsum ua kom tau raws li cov kev xav tau ntawm purity, impurity cov ntsiab lus, cov khoom sib xws, kev ua haujlwm raug, thiab lwm yam.

Post lub sij hawm: Aug-12-2022