High reputation Al/Nb Sputtering Target - Ti Sputtering Target high purity thin film PVD coating custom made – Rich

High reputation Al/Nb Sputtering Target - Ti Sputtering Target high purity thin film PVD coating custom made – Rich Detail:

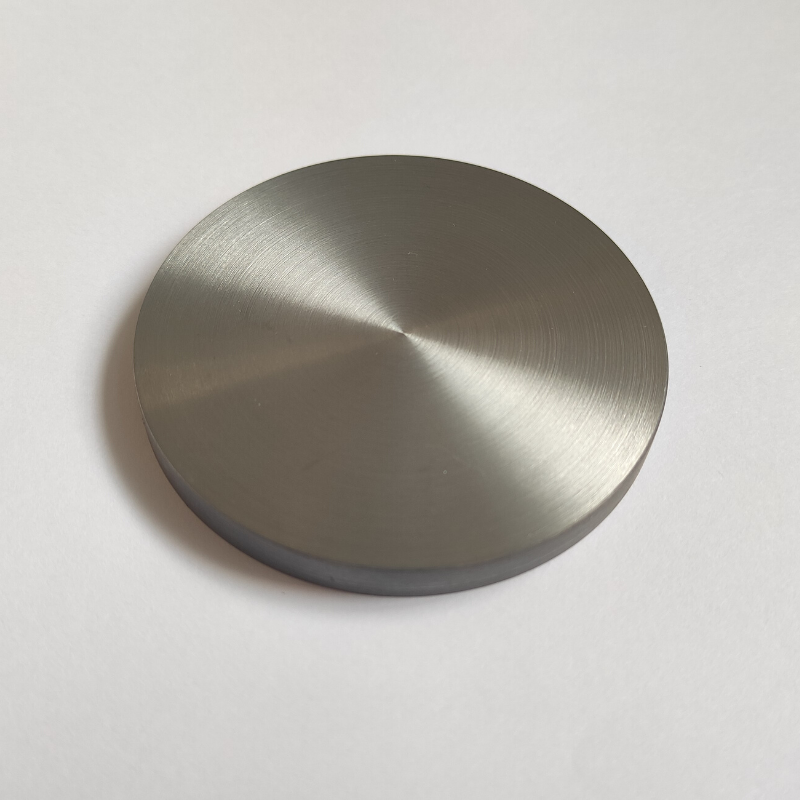

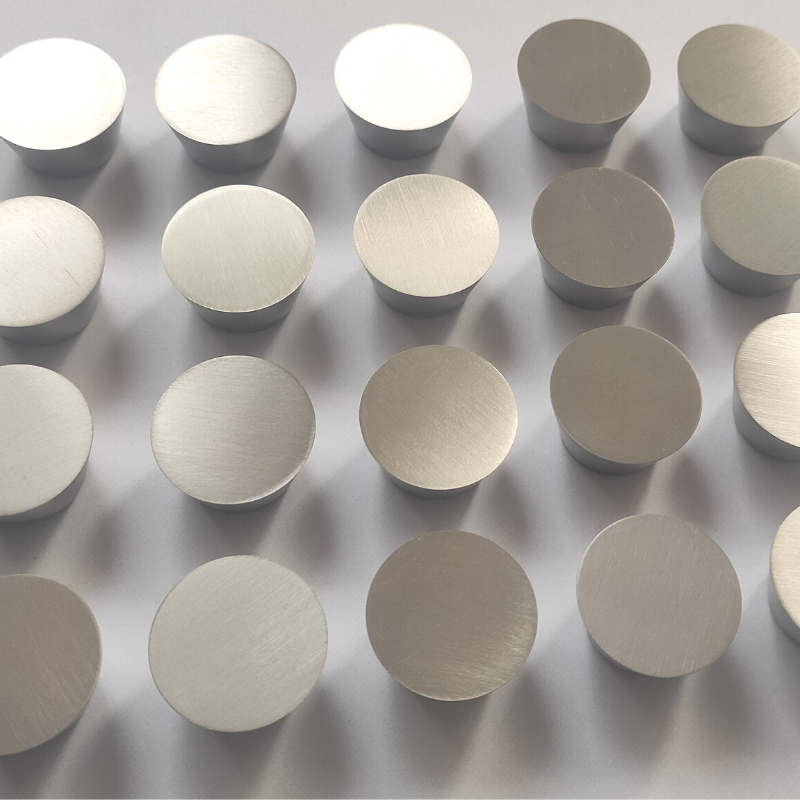

Titanium Sputtering Target Description

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a lustrous transition metal with a silver color. Its melting point is (1660±10)℃, boiling point is 3287℃. It has light weight, high hardness, corrosion resistance to all types of chlorine chemicals.

Titanium resists corrosion by seawater, and it can dissolve in both acidic and in alkaline media.

Titanium alloy is extensively used in aerospace, chemical engineering, petroleum, medicine, construction, and other fields for its outstanding properties, like low density, thermal conductivity and excellent corrosion resistance, weldability and biocompatibility.

Titanium could absorb hydrogen, CH4 and Co2 gases, and it is widely used in high vacuum and ultra-high vacuum systems. Titanium sputtering target could be used for the fabrication of LSI, VLSI and ULSI circuit network, or barrier metal materials.

Titanium Sputtering Target Packaging

Our Titanium sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Titanium sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Product detail pictures:

Related Product Guide:

With our outstanding administration, powerful technical capability and strict top quality handle procedure, we go on to provide our purchasers with reliable good quality, reasonable selling prices and excellent services. We goal at becoming certainly one of your most responsible partners and earning your gratification for High reputation Al/Nb Sputtering Target - Ti Sputtering Target high purity thin film PVD coating custom made – Rich , The product will supply to all over the world, such as: Turkey, Florence, Nepal, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.