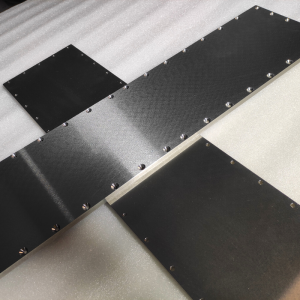

High quality High purity Factory price Cu Zn25 wt% Copper Zinc Alloy target CuZn targets for Metal Sputtering target

Chromium Cobalt

High quality High purity Factory price Cu Zn25 wt% Copper Zinc Alloy target CuZn targets for Metal Sputtering target,

Cu Zn25 wt% Copper Zinc Alloy target CuZn targets for Metal Sputtering target Factory price Cu Zn25 wt%,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.Copper Zinc alloy sputtering target is fabricated by means of powder metallurgy. The addition of zinc enhances the strength and ductility of the base copper material. The higher the concentration of zinc, the stronger and more pliable the alloy. High-strength brass contains more than 39% zinc. Copper Zinc alloy is conventionally called as Brass. Brass is a non-ferrous, red metal. Unlike the pure metal, however, it is a metal alloy that primarily consists of copper and zinc. Other metals—such as lead, tin, iron, aluminum, silicon, and manganese—are also added to produce more unique combinations of characteristics. Depending on the additional metals added to the alloy, it can demonstrate varying characteristics, such as a variable melting point or greater corrosion resistance.