High Purity 99.99% Aluminum Zinc Magnetron Sputtering Target Vacuum Coated Aluminum Zinc Target

Chromium Cobalt

High Purity 99.99% Aluminum Zinc Magnetron Sputtering Target Vacuum Coated Aluminum Zinc Target,

,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.Aluminum Zinc Alloy Sputtering Target

We accept Customized Purity and Shape.

Purity: 99.5%、99.7%、99.8%、99.9%、99.95%、99.99%.

Shape: Circular, Rectangular, Rod, Arc, Custom-Made…

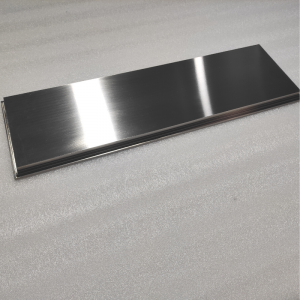

Details of Al Zn Alloy Sputtering Target

Al Zn Alloy Sputtering Target

Shape: Rod, Circular, Rectangular, Arc, Custom-Made.

Purity: 99.8%

MOQ: 1 Piece

Dispatch: 15 Days

Customization: Available

Application: Vacuum Coating

Aluminum zinc target is a target material obtained by high purity aluminum and zinc smelting casting, with uniform microstructure composition, high tensile strength and hardness, good damping performance, good wear resistance, small friction coefficient, and low friction temperature rise. It has gradually replaced wear-resistant parts such as turbines, bearings, slides, and threaded sleeves made of bronze and aluminum alloys in many fields. Aluminum zinc as a commonly used engineering materials, because of its collision does not produce sparks, so in the mining, petroleum, chemical and other fields have a broad market, can be used for most structural damping equipment, such as shock absorbing bearings, oil storage and transportation shock absorbers, etc., its microstructure is composed of the face center cubic α phase and dense row hexagonal η phase, by changing the chemical composition of the alloy to adjust the proportion of α phase and η phase, can change the ability of aluminum zinc to resist the impact load.

Aluminum zinc target through reaction sputtering to obtain AZO transparent electrode film, widely used in low-e glass, touch screen, liquid crystal display and other fields, due to the characteristics of aluminum zinc target, can be made of single large size target, and ceramic target compared with great advantages.