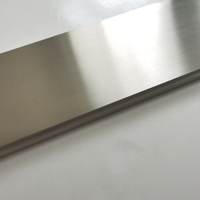

Me ka hoʻomaikaʻi ʻana i ka hana piha a me nā koi o ka ʻenehana noiʻi o ka ʻoihana uila, hōʻike pū ka molybdenum sputtering target i kāna hana kūʻokoʻa. Hiki i ka molybdenum sputtering target ke hana i nā kiʻiʻoniʻoni ma nā ʻano mea kumu. Hoʻohana nui ʻia kēia kiʻi sputtering i nā mea uila a me nā huahana uila. He aha ke ʻano o ka molybdenum sputtering target? ʻO kēia ka hōʻuluʻulu o RSM e kaʻana like

Ka hoʻokaʻawale ʻana i nā pahuhopu molybdenum sputtering

1. Paha pahu hopu

2, Huli hoololi

Ke kaʻina hana o ka molybdenum sputtering pahuhopu:

E koho i ke kaomi isostatic anuanu - sintering me ka umu wela waena - kawili ma ka wili wili - mīkini - ho'āʻo - huahana.

Hoʻohana i ka molybdenum sputtering mea pahuhopu:

Hoʻohana nui ʻia ka Molybdenum target material no nā ʻoihana e like me ke aniani conductive, STN/TN/ TFT-LCD, aniani optical, ion coating etc. kūpono no nā ʻōnaehana āpau o ka uhi mokulele a me ka uhi rotary.

Hoʻokumu ʻia kēia mau mea i nā hana o ka molybdenum o ka helu heheʻe kiʻekiʻe, ka conductivity uila kiʻekiʻe, ka impedance haʻahaʻa haʻahaʻa, ʻoi aku ka maikaʻi o ka corrosion, a me ka hana kūlohelohe. I ka wā ma mua, ʻo ka chromium ka mea uila nui o ka papa pālahalaha, akā me ka nui a me ke kiʻekiʻe kiʻekiʻe o ka hōʻike pālahalaha, ʻoi aku ka nui o nā mea me ka impedance kikoʻī haʻahaʻa e pono ai.

Eia kekahi, pono e noʻonoʻo ʻia ka palekana o ke kaiapuni. ʻO ka Molybdenum kekahi o nā mea i makemake ʻia no ka sputtering o ka hōʻike papa pālahalaha ma muli o kāna mau pono o ka 1/2 wale nō o ka impedance a me ke koʻikoʻi kiʻiʻoniʻoni i hoʻohālikelike ʻia me ka chromium a ʻaʻohe haumia kaiapuni.

Ka manawa hoʻouna: Iune-28-2022