Hoʻolauna kumu o ka pahu hao chromium alumini alumini:

ʻO ka pahu hao chromium aluminika pahu pahu he ʻano mea hao i haku ʻia me ka hao, chromium a me ka alumini. I waena o lākou, ʻo ka hao ka metala kumu, ʻo ka chromium ka mea hoʻoikaika paʻa, a ʻo ka alumini ka hana o ka stabilization. Ma muli o kona ikaika kiʻekiʻe, ke kūpaʻa kiʻekiʻe o ka mahana, ka pale ʻana i ka corrosion a me nā waiwai maikaʻi ʻē aʻe.

ʻO nā hiʻohiʻona o ka hao chromium alumini alumini:

1.Ka ikaika kiʻekiʻe: ferrochrome alumini alumini ka ikaika kiʻekiʻe, ʻoi aku kona ikaika ma mua o ke kila maʻamau, hiki ke hoʻokō i nā ʻano koi ikaika kiʻekiʻe o nā pono ʻenehana.

2. ʻO ke kūpaʻa wela kiʻekiʻe: ʻo ka ferrochrome aluminika alumini ka ikaika a me ka paʻa i nā wela kiʻekiʻe, a hiki ke hoʻohana ʻia no nā mea hana a me nā mea hana i nā wahi wela kiʻekiʻe.

3. Ke kū'ēʻana i ka corrosion: Ma hope o ka mālamaʻiaʻana o ka ili o ka ferrochrome alumini alumini, hiki iā ia ke pale i ka luhi, ka hakihaki a me nā pilikia'ē aʻe i hanaʻia e ka corrosion, i kūpono i ka moana, kemika a me nā mea'ē aʻe.

4. Machinability maikaʻi: Fe-Cr alumini alumini he machinability maikaʻi a hiki ke hoʻohana ʻia i ka hoʻolei ʻana, forging, plastic extrusion a me nā kaʻina hana ʻē aʻe.

Hoʻohana i ka hao chromium alumini alumini:

Ma muli o kāna mau waiwai kino a me ke kemika, hoʻohana nui ʻia ka FeCrAl alloy i ka mokulele, aerospace, automotive, chemical a me nā ʻano ʻē aʻe. Loaʻa i kāna ʻano hoʻohana i kekahi mau ʻano:

1. Nā kahua mokulele a me ka aerospace: Ma muli o kona ikaika kiʻekiʻe, ke kūpaʻa kiʻekiʻe o ka mahana, ka pale ʻana i ka corrosion a me nā ʻano ʻē aʻe, hoʻohana nui ʻia ka ferrochrome aluminika alumini i ka hana aerospace o ka hana a me ka mālama.

2. Kaʻa kaʻa: Ferrochrome alumini alumini ua hoʻohana nui ʻia i ka hana ʻana i nā ʻenekini kaʻa, nā pahu, nā pūpū, nā chassis a me nā ʻāpana ʻē aʻe.

3.Chemicalʻoihana: ferrochrome aluminika aluminika maikaʻi hoʻi i ka corrosion kū'ē a hiki ke kū'ē i ka waikawa, alkali a me nā meaʻino'ē aʻe, no laila ua hoʻohana nuiʻia i ka hanaʻana i nā mea hana kemika.

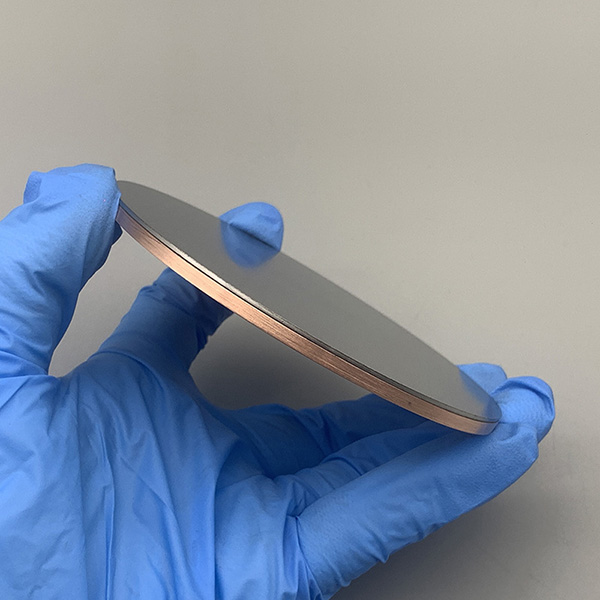

No ke aha e hoʻopaʻa ai ka sputtering target i kahi backplane?

1.Heat dissipation: I ka wā o ka sputtering kaʻina hana, e komo ka pahu hopu i ka nui o ka ikehu, e hopena i ka piʻi ʻana o ka mahana. ʻO ka hoʻopaʻa ʻana i ka mokulele hope me ka conductivity thermal kiʻekiʻe (e like me ka copper backplane) hiki ke alakaʻi maikaʻi i ka wela i hana ʻia e ka pahu hopu, mālama i ka paʻa o ka pahu hopu a me ka ʻaʻahu sputtering.

2. Kākoʻo Mechanical: Hoʻopili ʻia ka pahuhopu i ka hopena kino mau i ka wā o ka hoʻohana ʻana, a ʻo ka hoʻopaʻa ʻana i kahi backplane paʻa e hāʻawi i ke kākoʻo mechanical lawa e pale ai i ka pahuhopu mai ka haki ʻana a i ʻole deformation.

3.Improved ola lawelawe: Ma o ka hoʻopau wela wela a me ke kākoʻo mechanical o ka backplane, hiki ke hoʻemi ʻia ka poho a me ka deformation o ka pahu hopu, a laila e hoʻolōʻihi i ke ola lawelawe o ka pahuhopu.

4.Improved sputtering efficiency: Hiki i ka backplane ke kōkua i ka pahu hopu e loaʻa i ka ikehu o ka puna mana sputtering i ʻoi aku ka like, e loaʻa ana i kahi deposition kiʻiʻoniʻoni maikaʻi aʻe.

pehea e nakinaki ai i ka mokulele kua?

1. E hoʻomaʻamaʻa mua i ka ʻili o ka pahu pahu a me ka backplane ma mua o ka hoʻopaʻa ʻana

2. E kau i ka pahu hopu a me ka mokulele hope ma luna o ka pākaukau brazing a wela a hiki i ka wela paʻa

3.Metalize ka pahu hopu a me ka backplane

4.Glue i ka pahu hopu a me ka mokulele hope

5. Hoʻoluʻu

Ka manawa hoʻouna: Apr-10-2024