A waɗanne fagage ne aka fi amfani da maƙasudin jan ƙarfe mai tsabta? A kan wannan batu, bari edita daga RSM ya gabatar da filin aikace-aikacen babban maƙasudin jan ƙarfe ta hanyar abubuwan da ke gaba.

High tsarki jan hari hari da aka yafi amfani a Electronics da bayanai masana'antu, kamar hadedde da'irori, bayanai ajiya, LIQUID crystal nuni, Laser memory, lantarki iko na'urorin, da dai sauransu Za a iya amfani da a gilashin shafi filin; Hakanan za'a iya amfani dashi a cikin kayan da ba su da ƙarfi, juriya na lalata zafin jiki, samfuran kayan ado masu daraja da sauran masana'antu.

Masana'antar adana bayanai: Tare da ci gaba da haɓakar bayanai da fasahar kwamfuta, buƙatun rikodin kafofin watsa labarai yana ƙaruwa a kasuwannin duniya, kuma kasuwar kayan da ta dace don yin rikodin kafofin watsa labarai kuma tana faɗaɗa, samfuran da ke da alaƙa sun haɗa da diski mai wuya, magnetic head, na gani. fayafai (CD-ROM, CD-R, DVD-R, da sauransu), magneto-optical face canji na gani (MO, CD-RW, DVD-RAM).

Integrated kewaye masana'antu: a fagen semiconductor aikace-aikace, manufa shi ne daya daga cikin manyan sassa na kasa da kasa manufa kasuwar, akasari amfani da electrode interconnect fim, shãmaki film, lamba film, Tantancewar Disc mask, capacitor electrode film, juriya film da sauran al'amurran. .

Lebur nuni masana'antu: lebur nuni hada da ruwa crystal nuni (LCD), plasma nuni (PDP) da sauransu. A halin yanzu, nunin kristal na ruwa (LCD) yana mamaye kasuwar nunin panel panel, yana lissafin sama da 85% na kasuwa. Ana ɗaukarta a matsayin na'urar nunin allo mai ban sha'awa, ana amfani da ita sosai a cikin na'urori masu lura da kwamfyuta na kwamfutar tafi-da-gidanka, na'urorin kwamfuta na tebur da TELEBIJIN masu girma. Tsarin masana'anta na LCD yana da rikitarwa, a cikin abin da raguwar haske mai haske, m lantarki, emitter da cathode aka kafa ta hanyar sputtering, sabili da haka, a cikin LCD masana'antu, sputtering manufa taka muhimmiyar rawa.

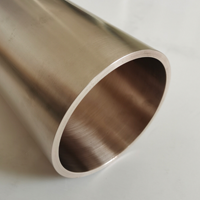

Babban tsaftataccen maƙasudin jan ƙarfe ana amfani dashi sosai a cikin filayen da ke sama, kuma ana gabatar da buƙatu mafi girma da mafi girma don ingancin maƙasudin sputtering.

Lokacin aikawa: Jul-07-2022