Menenejan karfe zinc gami (CuZn) sputtering manufa ?

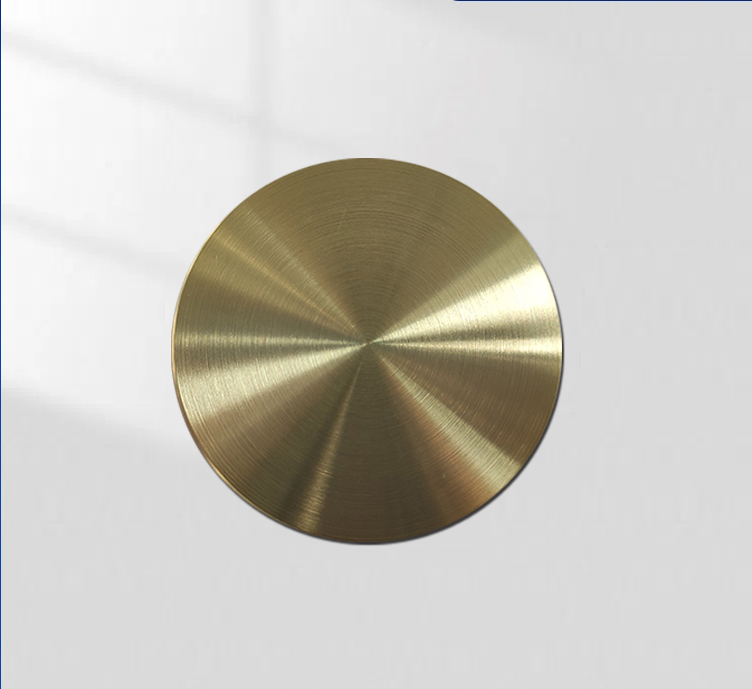

Makasudin sputtering jan ƙarfe shine manufa da aka samu ta hanyar narke tsattsauran jan ƙarfe da zinc, wanda kuma aka sani da manufa sputtering tagulla. Copper Zinc Alloy sputtering Target ne Madalla sputtering kayan a injin shafa masana'antu.

Menene fa'idodin jan ƙarfe da zinc hari?

Makasudin jan ƙarfe da zinc sun gaji wasu kyawawan halaye na jan ƙarfe, kamar ingantacciyar wutar lantarki da haɓakar yanayin zafi. High conductivity sa jan karfe da zinc hari taka muhimmiyar rawa wajen kera conductive hanyoyi a cikin na'urorin lantarki, yayin da high thermal watsin taimaka wajen yadda ya kamata canja wurin zafi a lokacin amfani, rage samar da zafi spots, da kuma inganta samar da inganci da ingancin samfurin.

Maƙasudin jan ƙarfe-zinc yana da fa'idar aikace-aikacen fa'ida a fagage da yawa saboda fa'idodinsa na babban tsabta, daidaito mai kyau, shiri mai sauƙi, ingantaccen juzu'i da daidaitawa.

Menene yanayin aikace-aikacen na jan ƙarfe da zinc hari?

1.Electronics masana'antu: Copper da zinc hari sun mamaye wani muhimmin matsayi a cikin masana'antar lantarki. Lokacin shirya fina-finai na bakin ciki, ana iya amfani da shi don haɓakar transistor, electrodes capacitor, da sauransu. Waɗannan aikace-aikacen suna da mahimmanci ga ingancin haɗaɗɗun da'irori da samar da fina-finai na bakin ciki. Sabili da haka, ingancin maƙasudin jan ƙarfe da zinc yana shafar aiki da amincin samfurin lantarki na ƙarshe.

2.Coating kayan: Copper da zinc hari kuma ana amfani da ko'ina a fagen kayan shafa. Babban tsabtarsa da daidaituwa ya sa ya dace don shirya kayan ado masu kyau. Ko a cikin abubuwan haɗin ƙarfe, kayan juriya mai zafin jiki ko samfuran kayan ado masu tsayi, maƙasudin jan ƙarfe da zinc na iya yin kyakkyawan aiki.

Kwayoyin 3.olar: Tare da saurin haɓakar makamashi mai sabuntawa, buƙatun jan ƙarfe da zinc a fagen ƙwayoyin rana kuma yana ƙaruwa. Makasudin jan karfe da zinc suna taka muhimmiyar rawa a cikin tsarin masana'anta na sel na hasken rana, suna taimakawa haɓaka haɓakar canjin photoelectric da rayuwar sabis na sel.

4.therapplication: Bugu da ƙari, ana amfani da maƙasudin jan ƙarfe da zinc a cikin masana'antar adana bayanai, irin su hard disk, magnetic head, diski na gani da sauran kayayyaki. A lokaci guda, a cikin masana'antar nunin lebur, jan ƙarfe da zinc ana amfani da su sosai a cikin kera samfuran nunin faifan ruwa (LCD) da samfuran nunin plasma (PDP).

Menene tsarin samar da maƙasudin jan ƙarfe da zinc?

1.Shirye-shiryen albarkatun kasa: Na farko, zaɓi jan ƙarfe mai tsabta da zinc azaman albarkatun ƙasa. Waɗannan albarkatun ƙasa suna yin gwaji mai ƙarfi da gwaji don tabbatar da cewa ingancinsu da tsabtarsu sun dace da buƙatun samarwa.

2.Melting da alloying: An shirya albarkatun tagulla da zinc a cikin tanderun narkewa a wani yanki na narkewa. A cikin aikin narkewar, ta hanyar sarrafa yanayin zafi da lokaci, jan ƙarfe da zinc suna gauraye gabaɗaya kuma sun isa daidaitaccen yanayi don samar da gami na jan karfe-zinc.

3.Casting and gyare-gyare: An narkar da jan ƙarfe da zinc gami a cikin ƙirar don simintin gyare-gyare da gyare-gyare. Wannan matakin yana buƙatar daidaitaccen sarrafa saurin simintin da zafin jiki don tabbatar da siffar da ake so da girman abin da ake so.

4.Processing da zafi magani: aiki da zafi magani na simintin jan karfe da zinc hari. Wannan ya haɗa da yankan, niƙa, gogewa da sauran matakai don kawar da ƙazanta da lahani da haɓaka ƙaƙƙarfan ƙaƙƙarfan manufa. A lokaci guda, microstructure da kaddarorin maƙasudin za a iya ƙara inganta su ta hanyar maganin zafi.

Ingancin dubawa da sarrafawa: A cikin dukkan tsarin samarwa, ana bincika da sarrafa maƙasudin jan ƙarfe da zinc. Wannan ya haɗa da nazarin abun da ke ciki, gwaji mai yawa, gwajin tauri, da dai sauransu, don tabbatar da cewa inganci da aikin abin da ake nufi ya dace da ka'idojin samarwa.

5.Cleaning and packing.

Lokacin aikawa: Afrilu-25-2024