Good User Reputation for Vacuum Sintering - Supply ODM Refractory High Entropy Alloy – Rich

Good User Reputation for Vacuum Sintering - Supply ODM Refractory High Entropy Alloy – Rich Detail:

All we do is always related with our tenet ” Client first, Have confidence in 1st, devoting about the meals packaging and environmental protection for Supply ODM Refractory High Entropy Alloy, We appreciate your enquiry and it’s our honor to work with every friend worldwide.

All we do is always related with our tenet ” Client first, Have confidence in 1st, devoting about the meals packaging and environmental protection for China Customized and Metal, With the advanced workshop, skilled design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our merchandise are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

Zinc is a blue-white, shiny metal. It has relatively low melting (419.5 °C) and boiling points (907 °C). At normal temperatures, it is brittle, but at temperatures of 100 °C to 150 °C, it becomes malleable.

When zinc is exposed to air, a film of carbonate forms on its surface, making it highly resistant to corrosion. Besides, Zinc is often used as a constituent of different types of alloys.

Impurity Analysis:

| Purity

≥ |

Composition(wt%)≤ | ||||||||

| Pb | Fe | Cd | Al | Sn | Cu | AS | Sb | Total | |

| 99.995 | 0.003 | 0.001 | 0.002 | 0.001 | 0.001 | 0.001 | - | - | 0.005 |

| 99.99 | 0.005 | 0.003 | 0.003 | 0.002 | 0.001 | 0.002 | - | - | 0.01 |

| 99.95 | 0.03 | 0.02 | 0.01 | 0.01 | 0.001 | 0.002 | - | - | 0.05 |

| 99.5 | 0.45 | 0.05 | 0.01 | - | - | - | 0.005 | 0.01 | 0.50 |

| 98.7 | 1.4 | 0.05 | 0.01 | - | - | - | - | - | 1.50 |

Zinc sputtering targets are extensively used in thin film coating, CD-ROM, decoration, flat panel display, optical lens, glass, and communication fields.

Rich Special Materials is a Manufacturer of Sputtering Target and could produce high purity Zinc Sputtering Materials according to Customers’ specifications. For more information, please contact us.

All we do is always related with our tenet ” Client first, Have confidence in 1st, devoting about the meals packaging and environmental protection for Supply ODM Refractory High Entropy Alloy, We appreciate your enquiry and it’s our honor to work with every friend worldwide.

Supply ODM China Customized and Metal, With the advanced workshop, skilled design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our merchandise are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

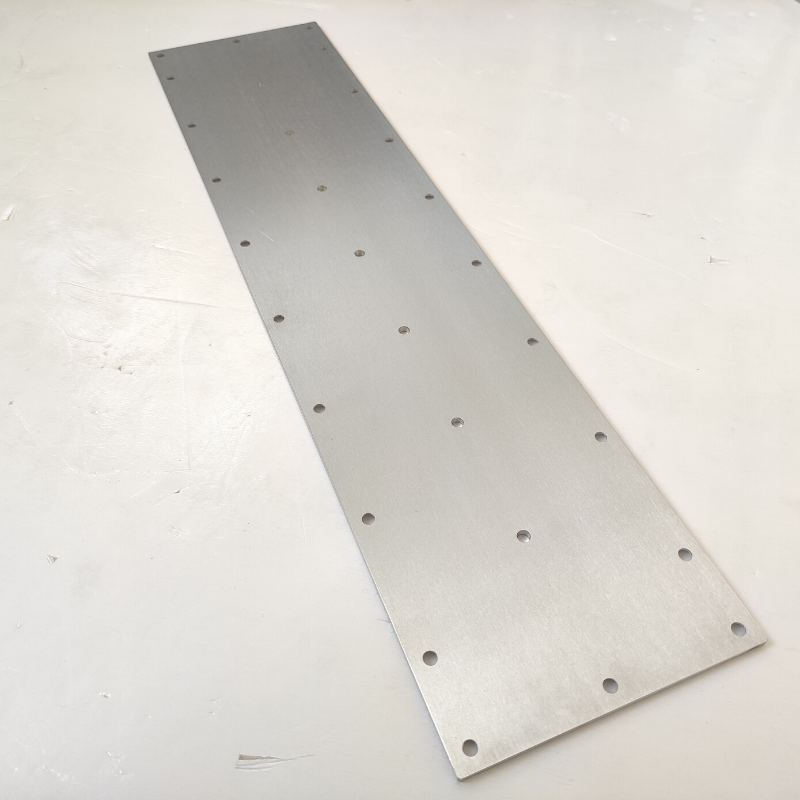

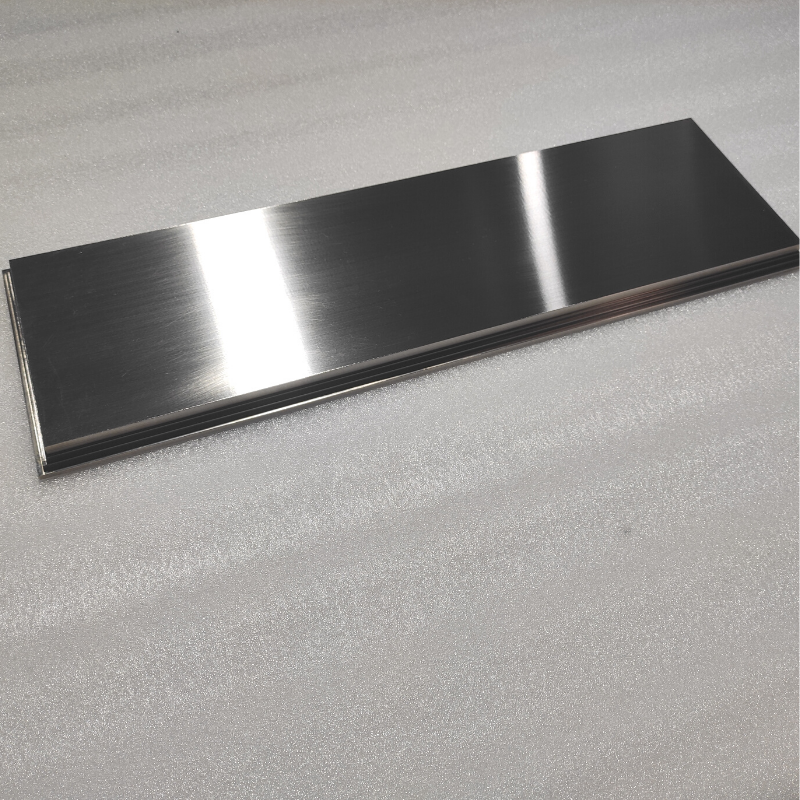

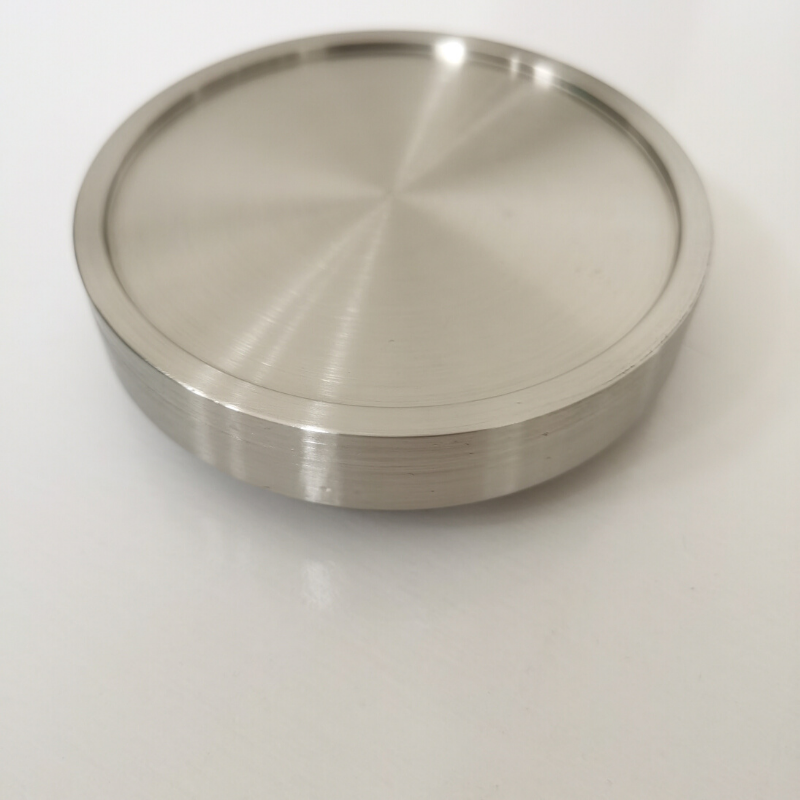

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new merchandise into the market each and every year for Good User Reputation for Vacuum Sintering - Supply ODM Refractory High Entropy Alloy – Rich , The product will supply to all over the world, such as: Vancouver, Haiti, Slovenia, With the principle of win-win, we hope to help you make more profits in the market. An opportunity is not to be caught, but to be created. Any trading companies or distributors from any countries are welcomed.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!