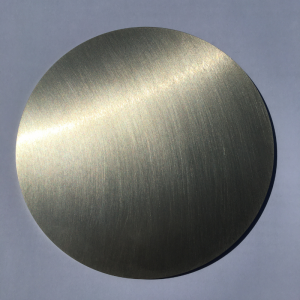

Good Quality Nickel chromium target NiCrAlY sputtering target coating material

Nickel Chromium Aluminum Yttrium

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for Good Quality Nickel chromium target NiCrAlY sputtering target coating material, We sincerely welcome all guests to set up business relationships with us on the basis of mutual benefits. Please contact us now. You will get our professional reply within 8 hours.

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we’ll continue to develop, to offer the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

Video

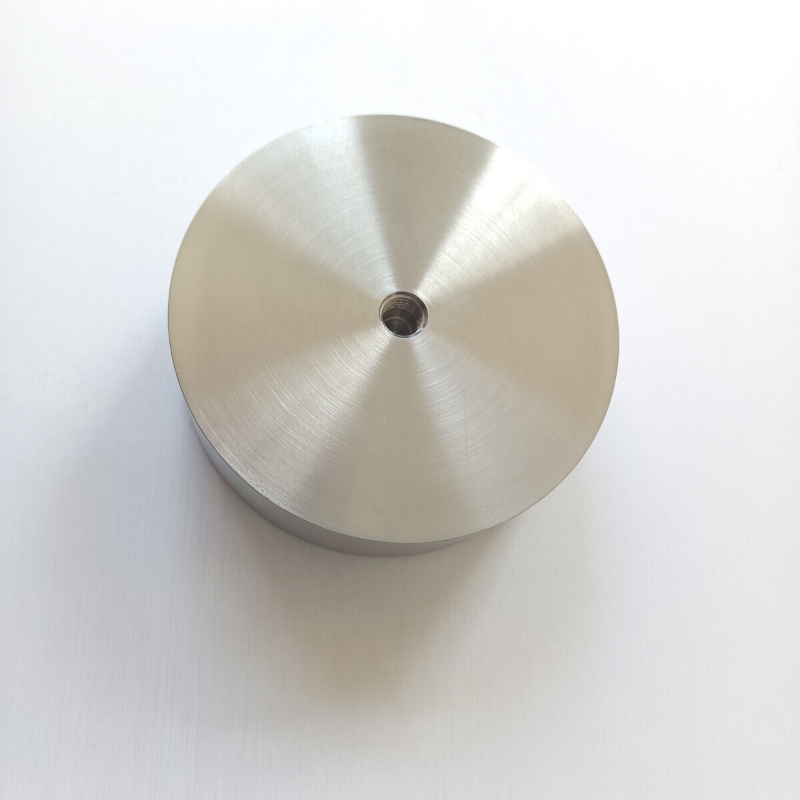

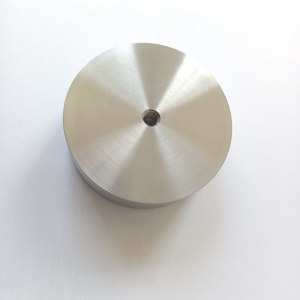

Nickel Chromium Aluminum Yttrium Sputtering Target Description

NiCrAlY Sputtering target is produced by Vacuum Melting of raw materials of Nickel Chromium Aluminum Yttrium. It has high consistency and fine grain size and no pores. Its composition of Chromium ranges from 10-30% (wt),Aluminum 10-20% (wt), Yttrium 0.5-1.0%(wt),and turn out the bi-layered structure of γ+β.

NiCrAlY layer is often used as thermal barrier coatings. High-temperature corrosion refers to a chemical attack of Chromia-forming Iron, Nickel and Cobalt-base Alloys from gases, solid or molten salts, or molten metals, typically at temperatures above 400°C (750ºF). The application of NiCrAlY layer used in the High Temperature Step Alloy of aircraft and gas turbine could improve the corrosion resisting performance and extend the product life.

Nickel Chromium Aluminum Yttrium Sputtering Target Packaging

Our Nickel Chromium Aluminum Yttrium sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Nickel Chromium Aluminum Yttrium sputtering targets are of ultra high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for Good Quality Nickel chromium target NiCrAlY sputtering target coating material, We sincerely welcome all guests to set up business relationships with us on the basis of mutual benefits. Please contact us now. You will get our professional reply within 8 hours.

Good Quality , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we’ll continue to develop, to offer the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.