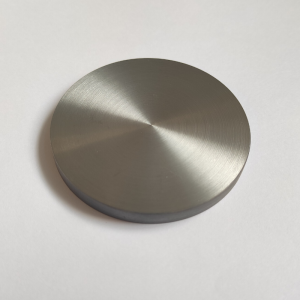

Factory source Molybdenum Sputtering Target for Sputter Deposition

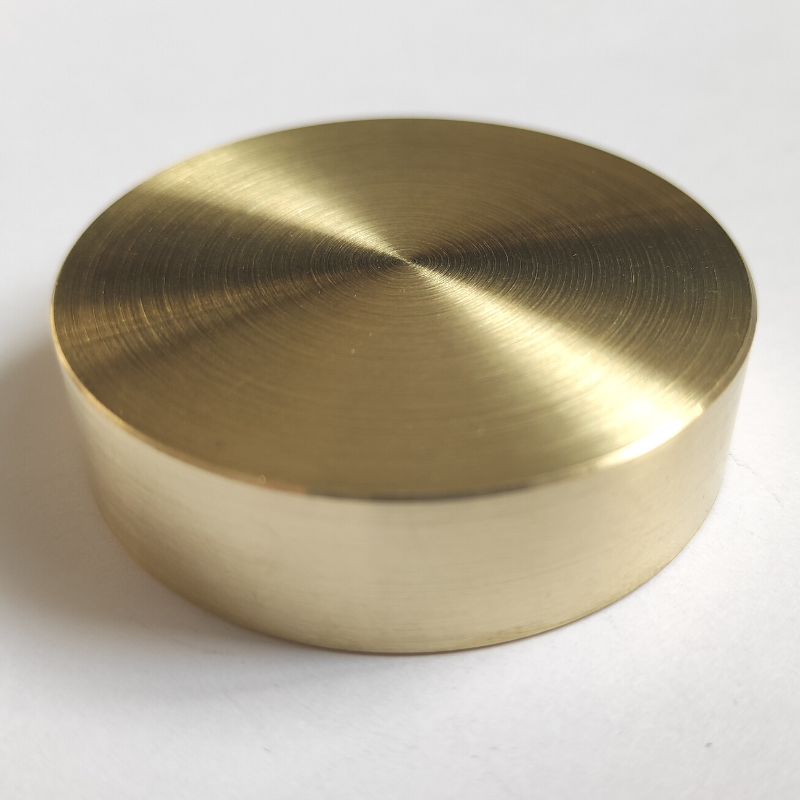

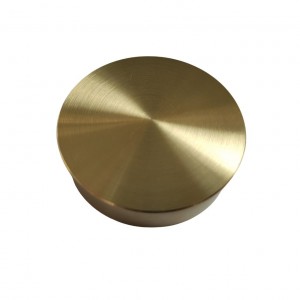

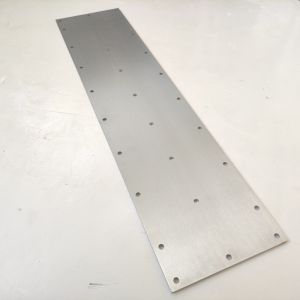

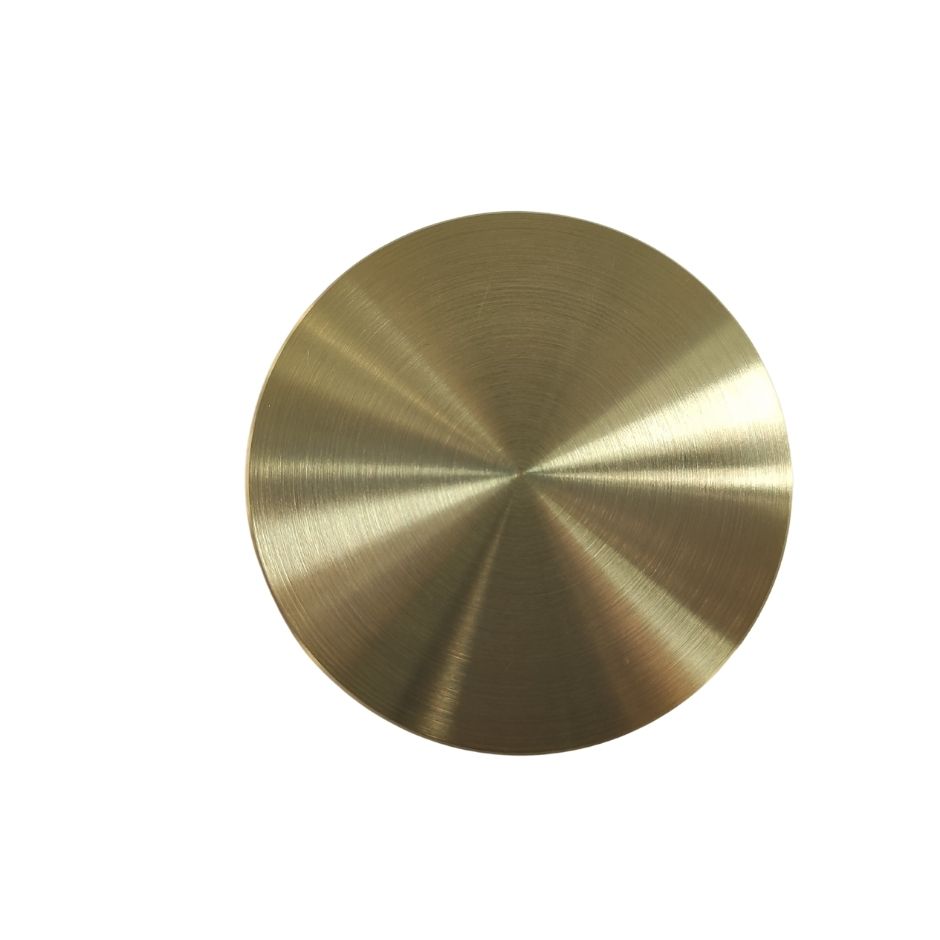

Copper Zinc

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for Factory source Molybdenum Sputtering Target for Sputter Deposition, We welcome new and aged prospects from all walks of existence to speak to us for potential company associations and mutual success!

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for China Molybdenum and Sputtering Metal System, Today, We are with great passion and sincerity to further fulfill our global customers’ needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Video

Copper Zinc alloy sputtering target is fabricated by means of powder metallurgy. The addition of zinc enhances the strength and ductility of the base copper material. The higher the concentration of zinc, the stronger and more pliable the alloy. High-strength brass contains more than 39% zinc. Copper Zinc alloy is conventionally called as Brass. Brass is a non-ferrous, red metal. Unlike the pure metal, however, it is a metal alloy that primarily consists of copper and zinc. Other metals—such as lead, tin, iron, aluminum, silicon, and manganese—are also added to produce more unique combinations of characteristics. Depending on the additional metals added to the alloy, it can demonstrate varying characteristics, such as a variable melting point or greater corrosion resistance.

|

ITEM |

Major Element(wt%) |

Impurity Element(ppm) |

|||||||

|

Element |

Cu |

Zn |

Fe |

Al |

Si |

C |

N |

O |

S |

|

Spec |

Balance |

0~40 |

200 |

100 |

100 |

100 |

100 |

100 |

50 |

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Copper Zinc Sputtering Materials according to Customers’ specifications. We could supply Copper Zinc targets with purity up to 99.95%, high density, appealing appearance, and the content of Zinc up to 40%, which could produce coatings with excellent mechanical properties, homogeneous structure, polished surface with no segregation, pores or cracks. For more information, please contact us.

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for Factory source Molybdenum Sputtering Target for Sputter Deposition, We welcome new and aged prospects from all walks of existence to speak to us for potential company associations and mutual success!

Factory source China Molybdenum and Sputtering Metal System, Today, We are with great passion and sincerity to further fulfill our global customers’ needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.