factory customized Zinc Zn Sputtering Target - High Purity 99.7% Al-Sn20-Cu1 wt% Aluminium Stannum Copper Tube target PVD Sputtering Mental Alloy Target – Rich

factory customized Zinc Zn Sputtering Target - High Purity 99.7% Al-Sn20-Cu1 wt% Aluminium Stannum Copper Tube target PVD Sputtering Mental Alloy Target – Rich Detail:

High Purity 99.7% Al-Sn20-Cu1 wt% Aluminium Stannum Copper Tube target PVD Sputtering Mental Alloy Target,

,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.

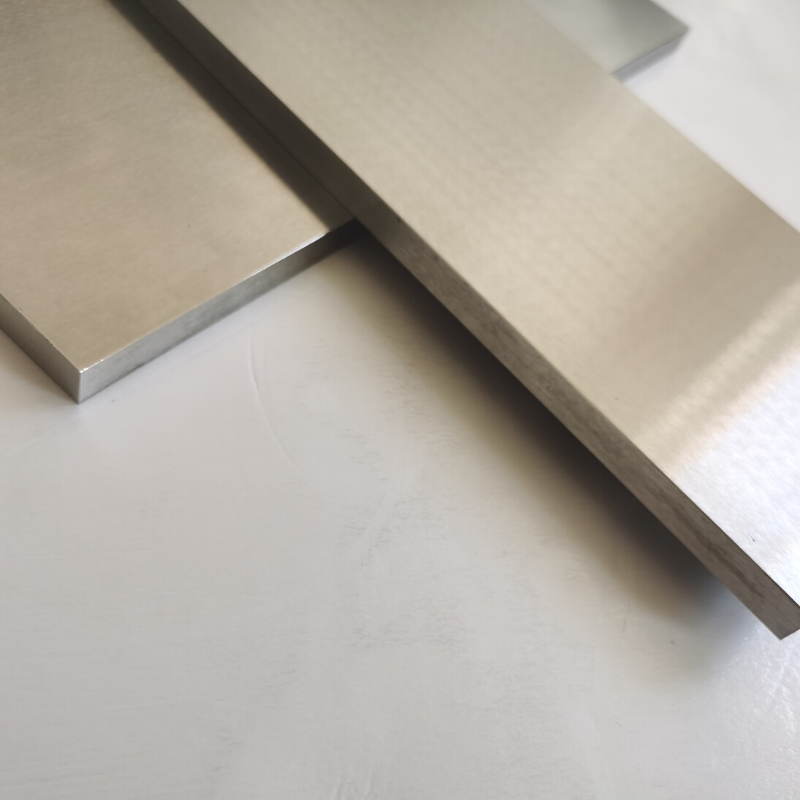

The AlSnCu alloy sputtering target is produced using smelting technology and is rolled to make it more densified. It is generally used for engine coating. After the aluminum-tin copper coating is heat treated, the tin forms a mesh structure on the substrate, and the addition of copper increases the hardness of the coating. Due to the moderate hardness of the alloy, it has high fatigue strength, load carrying capacity and sliding speed, and has good wear resistance and corrosion resistance, making it a good choice for medium speed medium load engine bearings.

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for factory customized Zinc Zn Sputtering Target - High Purity 99.7% Al-Sn20-Cu1 wt% Aluminium Stannum Copper Tube target PVD Sputtering Mental Alloy Target – Rich , The product will supply to all over the world, such as: Swansea, Mexico, India, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!