Customization Fast Delivery Vacuum Coating Materials Copper Tungsten Sputtering Target Cu W Target

Chromium Cobalt

Customization Fast Delivery Vacuum Coating Materials Copper Tungsten Sputtering Target Cu W Target,

Vacuum Coating Materials Cu W Target Copper Tungsten Sputtering Target,

Chromium cobalt sputtering target from Rich Special Materials is a silvery alloy sputtering material containing Cr and Co.

Chromium is a chemical element that originated from the Greek ‘chroma’, meaning color. It was early used before 1 AD and discovered by Terracotta Army. “Cr” is the canonical chemical symbol of chromium. Its atomic number in the periodic table of elements is 24 with a location at Period 4 and Group 6, belonging to the d-block. The relative atomic mass of chromium is 51.9961(6) Dalton, the number in the brackets indicating the uncertainty.

Cobalt is a chemical element that originated from the German word ‘kobald’, meaning goblin. It was first mentioned in 1732 and observed by G. Brandt. “Co” is the canonical chemical symbol of cobalt. Its atomic number in the periodic table of elements is 27 with a location at Period 4 and Group 9, belonging to the d-block. The relative atomic mass of cobalt is 58.933195(5) Dalton, the number in the brackets indicating the uncertainty.

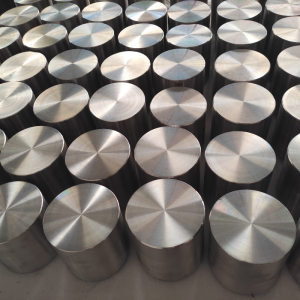

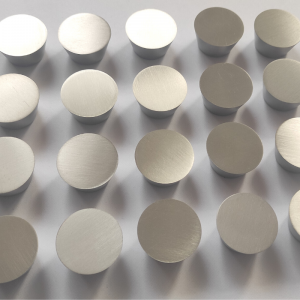

Chronium Cobalt Sputtering Targets are manufactured by means of Vacuum Melting and PM. CrCo has superior specific strength and has been used in various fields where high wear-resistance was needed including aerospace industry, cutlery, bearings, blades, etc.

Rich Special Materials specializes in the Manufacture of Sputtering Target and could produce Chronium Cobalt Sputtering Materials according to Customers’ specifications. For more information, please contact us.Copper Tungsten alloy sputtering target is fabricated by means of powder metallurgy. The content of copper ranges mostly between 10% and 50%. It has excellent thermal and electric conductivity, high temperature strength and ductility. At very high temperatures, such as above 3000°C, the copper in the alloy is liquefied and evaporated, absorbing a large amount of heat, and reducing the surface temperature of the material. This kind of material is also called metal sweating material.

Since the two metals of Tungsten and Copper are incompatible with each other, Copper-Tungsten alloy has the low expansion, wear resistance, corrosion resistance of tungsten and the high electrical and thermal conductivity of copper, and it is suitable for various mechanical processing. Copper Tungsten alloys can be produced according to user requirements for Copper-Tungsten ratio production and size processing. Copper-Tungsten alloys generally use powder metallurgy processes to prepare powder-batch mixing-press molding-sintering infiltration.