Cr30Al70 at% High Purity 99.80% Sputtering Target Metal target Alloy Material

Lead-Bismuth

Cr30Al70 at% High Purity 99.80% Sputtering Target Metal target Alloy Material,

,

Lead-Bismuth Sputtering Target Description

Lead Bismuth alloy is known for its low melting point. Low melting temperature alloys usually contain about 20% to 25% lead, Bismuth, and sometimes other metals, like Tin, Cadmium, or Indium. They are widely used in optical industry for lens blocking, work-holding in precision engineering, prototyping, safety valves, press tools for limited runs, tube bending for complicated profiles, radiotherapy to construct shielding blocks and many other applications.

Lead-Bismuth alloy has a melting point of 124°C, it is a suitable material for coolant in nuclear reactors, Hydrogen production, and spallation targets for non-fission neutron production.

Low melting temperature alloy Ingredient

|

No |

Composition(wt.%) |

Melting zone temperature /℃ |

Purity |

Tips |

|||||

|

Bi |

Pb |

Sn |

Cd |

Start |

Finish |

Self weight flow point |

(%) | ||

|

1 |

50.0 |

26.7 |

13.3 |

10.0 |

70 |

70 |

70 |

eutectic |

|

|

2 |

52.0 |

32.0 |

16.0 |

- |

95 |

95 |

95 |

eutectic |

|

|

3 |

54.4 |

43.6 |

1.0 |

1.0 |

104 |

115 |

112 |

Non- eutectic |

|

|

4 |

55.5 |

44.5 |

- |

- |

- |

- |

- |

99.995 |

|

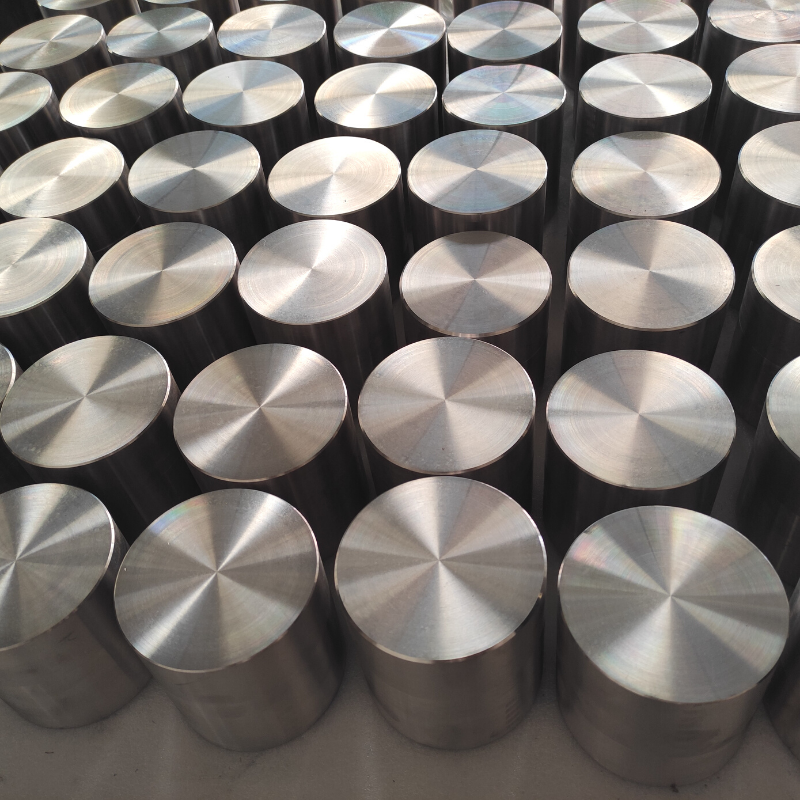

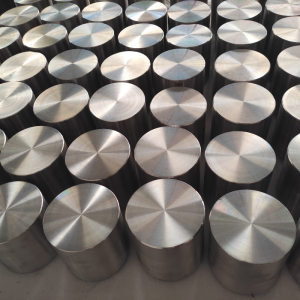

Lead Bismuth Sputtering Target Packaging

Our Lead Bismuth sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

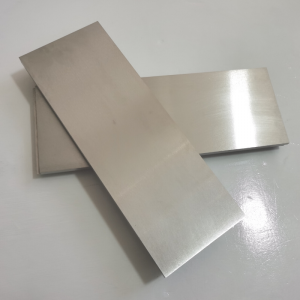

Get Contact

RSM’s Lead Bismuth sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.The fabrication of Chronium Silicon Sputtering Targets comprises the following steps:

1. Powder grinding and mixing.

2. Hot isostatic pressing treatment to get semi-finished products.

3. Machining the rough chromium-silicon alloy sputtering target material to obtain the chromium-silicon alloy sputtering target material.

During the deposition process of AlCr sputtering targets, a hard Aluminium-Chrom-Nitrid (AlCrN) coating is formed. This coating

shows high hardness and oxidation resistance properties even at high temperature. The cutters could run at high feeds to increase

productivity and raise quality when using CNC machines.