Competitive Price for Cold Isostatic Pressing - Cralsi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich

Competitive Price for Cold Isostatic Pressing - Cralsi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich Detail:

Chronium Aluminum Silicon Sputtering Target Description

The fabrication of Chronium Aluminum Silicon Sputtering Targets comprises the following steps:

1.Vacuum melting of Silicon, Aluminum and Chronium to obtain step alloys.

2.Powder grinding and mixing.

3.Hot isostatic pressing treatment to obtain the chromium Aluminum silicon alloy sputtering target.

Chronium Aluminum Silicon Sputtering Targets are extensively used in cutting tools and molds, owing to its wear resistance and high temperature oxidation resistance to improve the film performance.

An amorphous Si3N4 phase would be formed during the process of PVD of CrAlSi targets. Due to the incorporation of amorphous Si3N4 phase, the growth of the grain size could be restrained and improve the high temperature oxidation resistance property.

Chronium Aluminum Silicon Sputtering Target Packaging

Our Chronium Aluminum Silicon sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation

Get Contact

RSM’s Chronium Aluminum Silicon sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.

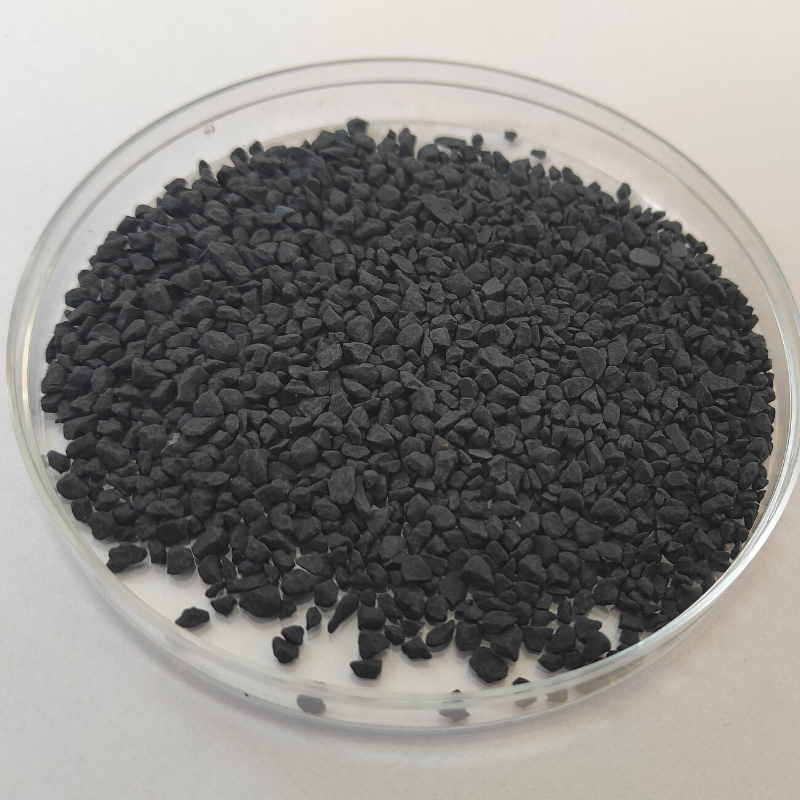

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Competitive Price for Cold Isostatic Pressing - Cralsi Alloy Sputtering Target High Purity Thin Film Pvd Coating Custom Made – Rich , The product will supply to all over the world, such as: Sydney, Cyprus, luzern, So far our products have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.